Our Business

We deliver high-quality products to customers around the world.

Based at our plant on Cebu Island in the Philippines, ATOMED CEBU manufactures and exports a wide range of products, from medical disposables to infant incubators Manufacturing of OEM Products for our group company, ATOM MEDICAL CORPORATION.

With the latest equipment in clean rooms and hygienic environments, and under strict quality control, we provide highly reliable products to countries around the world.

Production System

Strengths of ATOMED CEBU

-

01

Integrated

manufacturing

line -

02

Diverse

manufacturing

capabilities -

03

Strict

quality

control

-

01. Shortening lead times with an integrated manufacturing line.

For manufacturing medical disposables, we have an integrated manufacturing line capable of handling all processes in-house, from raw material molding, assembly, and quality inspection, to packaging, sterilization, and shipment. This system enable us to respond flexibly to short lead times and small-lot production, and to quickly meet the diverse needs of medical facilities.

-

02. Equipped with large molding machines, capable of manufacturing a wide range of products.

ATOMED CEBU has large molding machines, allowing in-house integrated molding of both small medical disposables and large components such as infant incubator bodies. The ability to manufacture large components without seams enhances product strength and helps maintain hygiene. During development, this also enables highly flexible design, resulting in the creation of a wide variety of products.

-

03. Strict quality control and a strong commitment to continuous improvement.

We have a dual verification system, combining 100% inspections with random checks. In addition, because we maintain strict lot control of our products, we can quickly identify the cause and implement corrective measures in the unlikely event of a defect. Furthermore, we actively engage in QC activities, where teams collaboratively explore solutions to challenging issues. Together, these efforts foster a mindset of continuous improvement in all our operations.

Production Facilities and Processes

At our plant, we utilize the latest equipment and continuously strive to make production processes efficient. In order to produce high-quality products, we thoroughly manage every stage, including raw material receipt, molding, assembly, quality inspection, and packaging, while observing rigorous standards.

-

Extrusion molding

-

Injection molding

-

Package making

-

Production assembly

-

Sterilization operations

Manufacturing of OEM Products

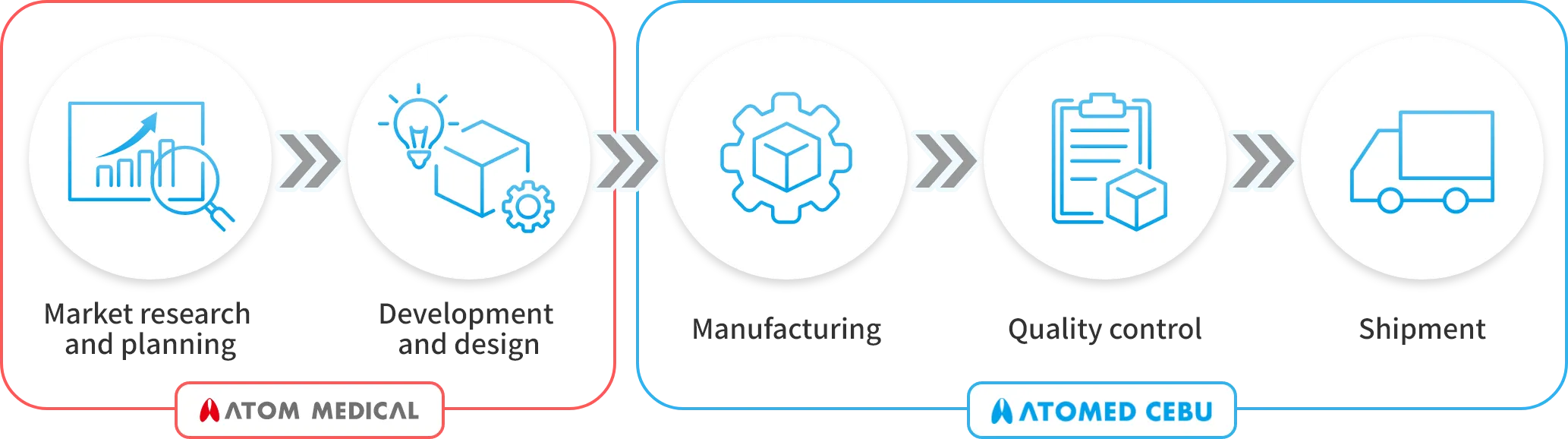

We maintain a reliable, integrated system from market research for medical products through manufacturing and shipment.

Based on the broad medical product manufacturing expertise cultivated over many years by the ATOM MEDICAL Group, we deliver Manufacturing of OEM Products tailored to the requirements of our customers.

We provide comprehensive support, from market research and development through manufacturing and shipment.

We maintain strict quality control and are capable of providing flexible OEM supply to satisfy customer requirements.